Quo Vadis Process Flowsheet Optimization?

Without doubt, there has been a tremendous progress in process simulation in the last 30 years. It is possible to simulate flowsheets with 200.000 equations and dozens of recycle streams, to enhance the plant data with online models, and to study the dynamic behaviour. But what about process optimization? That means the automated search for the best process design, the best operating point, or the best trajectory according to a defined objective function.

Here, there is big gap of what has been developed in academia and of what is being applied in industry. Besides the optimization and debottlenecking of chemical processes, the upcoming energy transition and bioeconomy should be enough motivation to aim for the best or at least significantly better solutions with respect to energy consumption, capital investment, or CO2 footprint.

challenges

Taking the example of the simultaneous optimization of operational and structural degrees of freedom, which leads to a mixed-integer nonlinear programming (MINLP) problem, there are two main reasons why MINLP is not applied routinely according to the author’s opinion:

- Lack of robustness: Every optimization algorithm requires at some point a converged flowsheet. The mass and component balance are hard constraints in chemical engineering unlike in other disciplines and not easy to fulfil. Good initial values and in-depth problem understanding are required. In other words, you should have an already good understanding about the location of the optimum before you start. Although optimization algorithms for large flowsheets were developed and implemented in most commercial process simulators, they are not frequently used in practice.

- No guarantee for global optimum or the curse of nonconvexity: Every flowsheet contains nonconvex equations due to the multiplication of flow rates and concentrations and physical property models, for example, to calculate the VLE. This is especially pronounced for MINLP problems. The algorithm may find a suboptimal solution that is far from the global optimum [1].

And there are new challenges coming up. The changing feedstock and raw material and energy prices in the upcoming bioeconomy will require flexible processes which will lead to optimization under uncertainty [2].

new developments

Fortunately, there are a new developments to tackle the aforementioned challenges. One approach is the decomposition approach which decomposes flowsheet into separate unit operations and the optimization variables into complicating and non-complicating variables to provide good or even global optimal solutions [3].

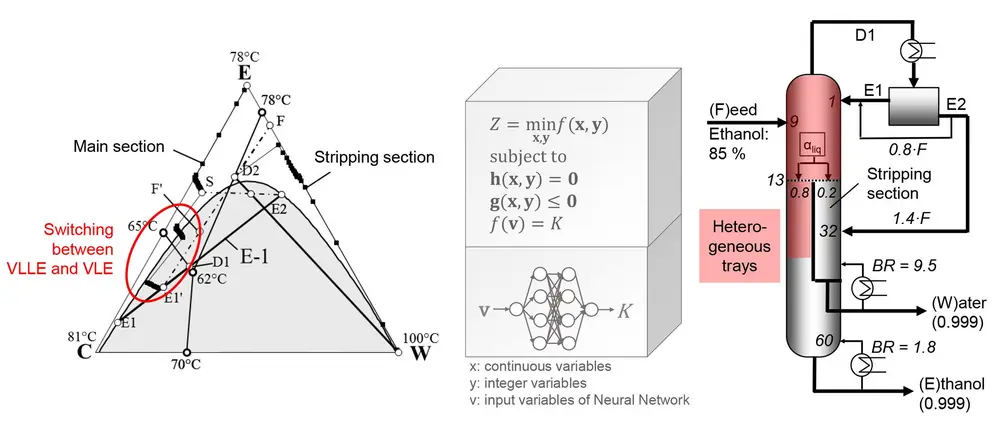

Artificial intelligence (AI) will further improve flowsheet convergence. One example are so-called hybrid models. Machine learning methods will substitute difficult physical property calculations (see Figure 1).

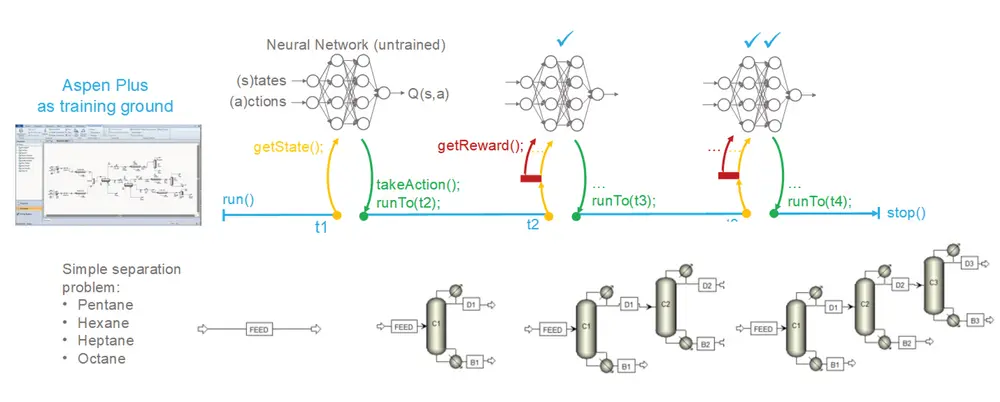

Another promising method from AI is reinforcement learning (RL). An agent performs an action according to its policy and receives a reward or punishment (see Figure 2). By repeating this process, the policy will improve and under certain conditions even be optimal. The training of RL agents requires a lot of data and what is better suited than a process simulator as the training ground? However, the prerequisite here is a robust flowsheet simulation as well.

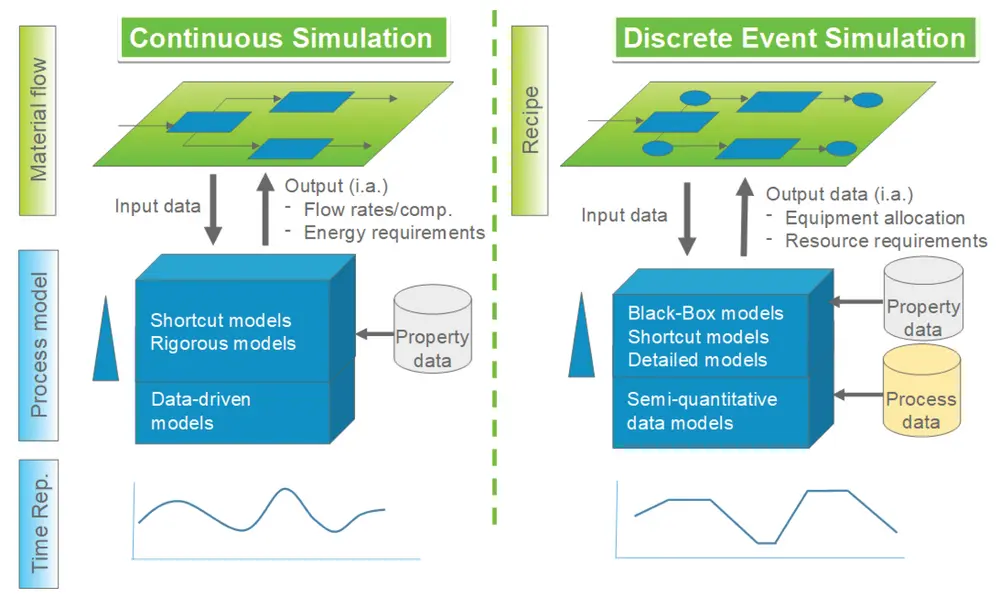

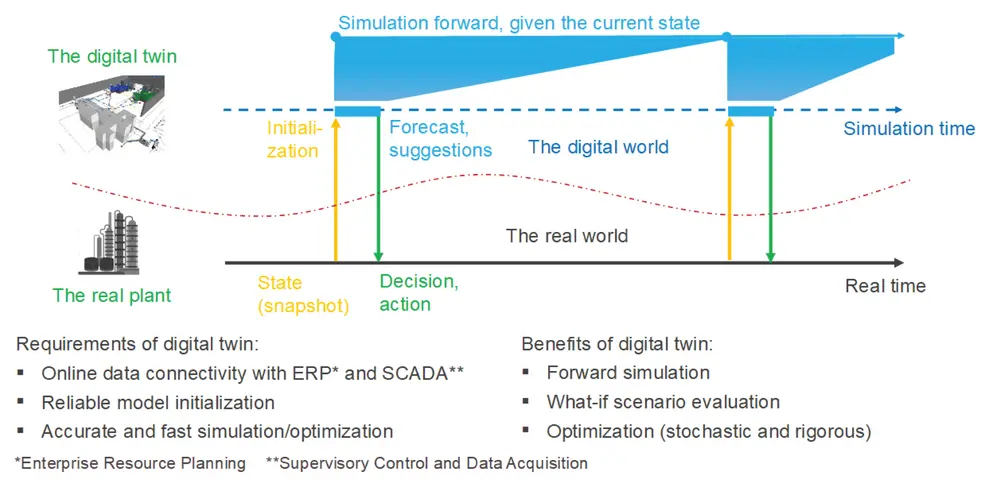

Traditionally, the simulation of continuous processes plays a more prominent role in research and education. Due the inherent unsteady nature, it is not practical to model a complete flowsheet with a set of differential equations. Instead discrete event simulation (DES) is used to model a complete plant or even site. In contrast to continuous simulation, batch process simulation requires much more process data (see Figure 3). The models are the basis for digital twins (see Figure 4) and are being increasingly used in industry [4].

optimization methods in industry

How to improve the transfer of optimization methods from academia to industry?

- Transparency and comparability: It is necessary to provide source codes like chemists provide their lab recipes for chemical synthesis. The methods have to be evaluated with test libraries and predefined metrics.

- Collaboration: Collaboration between chemical engineers, applied mathematicians as well researchers and practitioners from other disciplines is important. Especially, in optimization and machine learning, chemical engineers can benefit from other disciplines like operations research and discrete manufacturing.

- Deployment: The developed methods have to be easy to use by engineers in their daily working life. Commercial tools like Aspen Plus or gPROMS require optimization interfaces and web-based applications to deploy methods to non-expert users.

- Training: Last, but not least, chemical engineers require a basic understanding of optimization and machine learning methods. Due to already fully loaded curricula, this can be deepened in elective courses and Master theses.

Literature

[1] Franke (2017), Chem. Ing. Tech., 89(5), p. 582

[2] Mitsos et al. (2018), Comp. Chem. Eng., 113, p. 209

[3] Franke (2019), Comp. Chem. Eng., 131, p. 106583

[4] INOSIM (2021), retrieved from www.inosim.com/first-optiprod-nrw-year-completed