Transforming chemical engineering with Artificial Intelligence

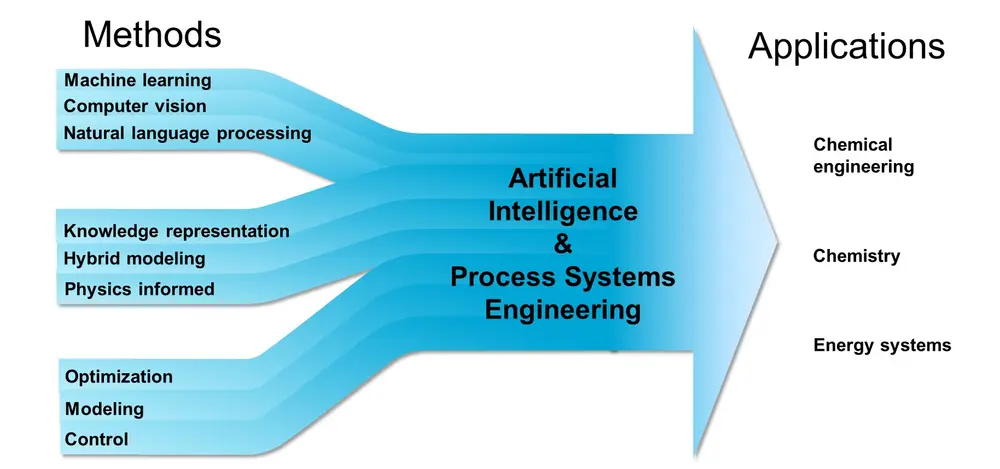

Artificial Intelligence (AI) led to tremendous success in automated decision-making in various domains even surpassing human performance. AI has transformed some domains such as computer vision where it is driving innovation at an enormous speed. However, it seems, that the full potential of AI has not yet been unfolded in chemical engineering. In particular, it is unclear if and how AI can transform the way we design and operate (bio)-chemical processes.

Vision

We are the Process Intelligence Research group (www.pi-research.org) at the Department of Chemical Engineering at Delft University of Technology. Our vision is the transformation of chemical engineering with AI to design and operate sustainable process solutions. We bridge chemical engineering and AI to deliver the next generation of intelligent knowledge and decision-making platforms for the chemical engineering field.

At the heart of the envisioned transformation lies our fundamental and applied research in machine learning, data science, and process systems engineering (PSE). To bring our vision to life and create impact in society, we closely collaborate with industry and academic partners.

"The full potential of AI has not yet been unfolded in chemical engineering"

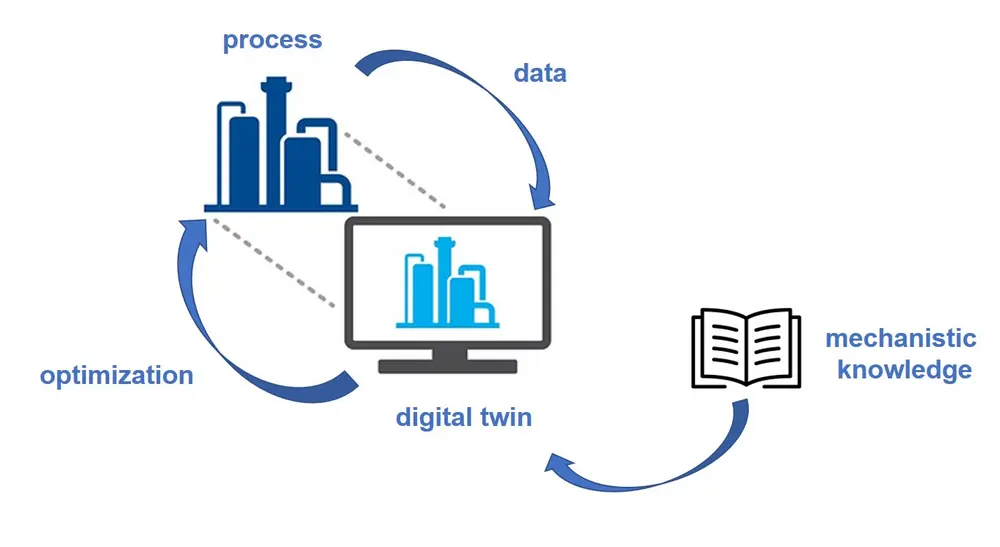

Hybrid physical and machine learning models

The application of black-box models for chemical engineering process operation is challenging because they require large amounts of data, their predictions are not explainable, and there are safety concerns.

Hybrid modeling combines mechanistic models with machine learning. They can increase the reliability, safety, explainability, and extrapolability. In addition, hybrid modeling can overcome the curse of dimensionality and thereby reduce data requirements drastically. However, the integration of knowledge into deep learning structures is still limited in practice because it requires interdisciplinary research between PSE and machine learning. Also, the consideration of real process time series data calls for collaborations between industry and academia.

Knowledge graphs structure our data

The lack of meaningful data representations and the lack of structured big data hinders breakthroughs of AI in chemical engineering. Engineers use a many tools in their daily work to handle data from different sources and formats. Essentially, engineers integrate heterogeneous information manually. For example, engineers combine information from P&IDs, process simulations, and chemical data bases to perform Hazard and Operability (HAZOP) studies.

Structuring and linking the heterogeneous and interdisciplinary information will open up new potentials for AI. It has the potential to facilitate the automation of multiple engineering workflows. Knowledge graphs present a potential avenue to link heterogeneous data from various sources. We are developing the Chemical Engineering Knowledge Graph which links information from P&IDs, process simulations, DFT simulations, molecular properties, patents, publications, and operational data.

Digitization of flowsheets

The digitization of conventional paper-based flowsheets and P&IDs is necessary to build virtual plant models. However, manual conversion is costly. The goal of flowsheet digitization is to extract the process topologies from the flowsheet images and save them in a machine-readable graph format. We develop and maintain software to digitize engineering documents like flowsheets and P&IDs. The digitization of chemical process flowsheets involves object detection algorithms and a pathway exploration algorithm. In the object detection step, AI models identify the position and type of unit operation in the flowsheet. In the pathway exploration step, the connectivity of the unit operations is explored. Moreover, text and tables are identified and digitized.

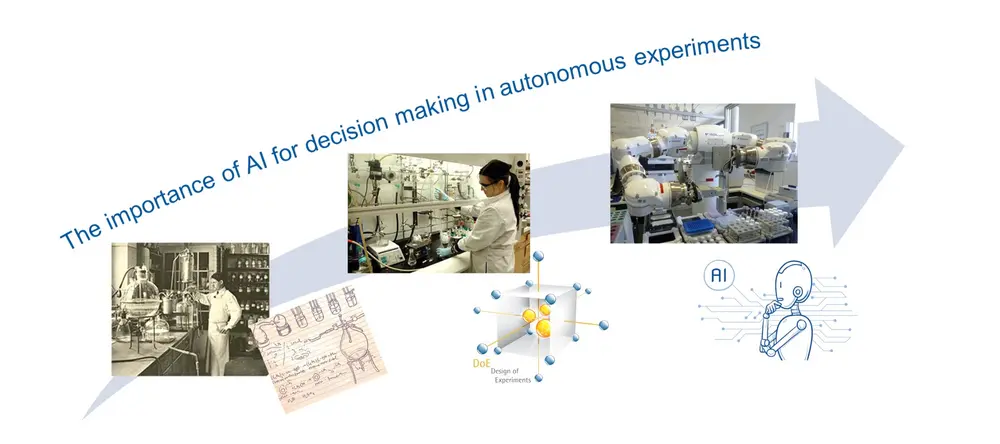

AI for autonomous labs

Autonomous reaction platforms and robots are increasingly popular in chemistry and biotechnology laboratories. While the automation of lab workflows is realized through automation, fully autonomous systems also require intelligent algorithms that design experiments. AI algorithms have the potential to learn from previous experience to design meaningful experiments. However, deep learning systems are often not suitable because they require big data. We use Gaussian processes and tailored Bayesian optimization algorithms that determine optimal reaction conditions, solvents, and catalysts in a minimum number of experiments.

Contact:

Process Intelligence Research group

Prof. Dr. Artur M. Schweidtmann

a.schweidtmann@tudelft.nl

https://www.pi-research.org/